Ultrafiltration System

Ultrafiltration System

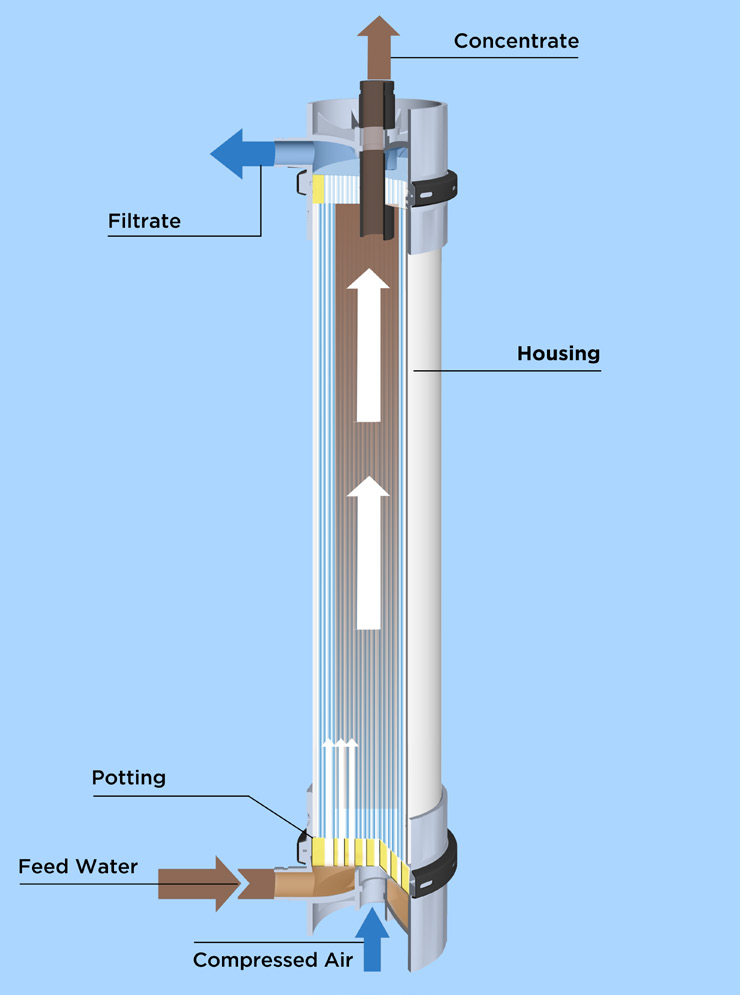

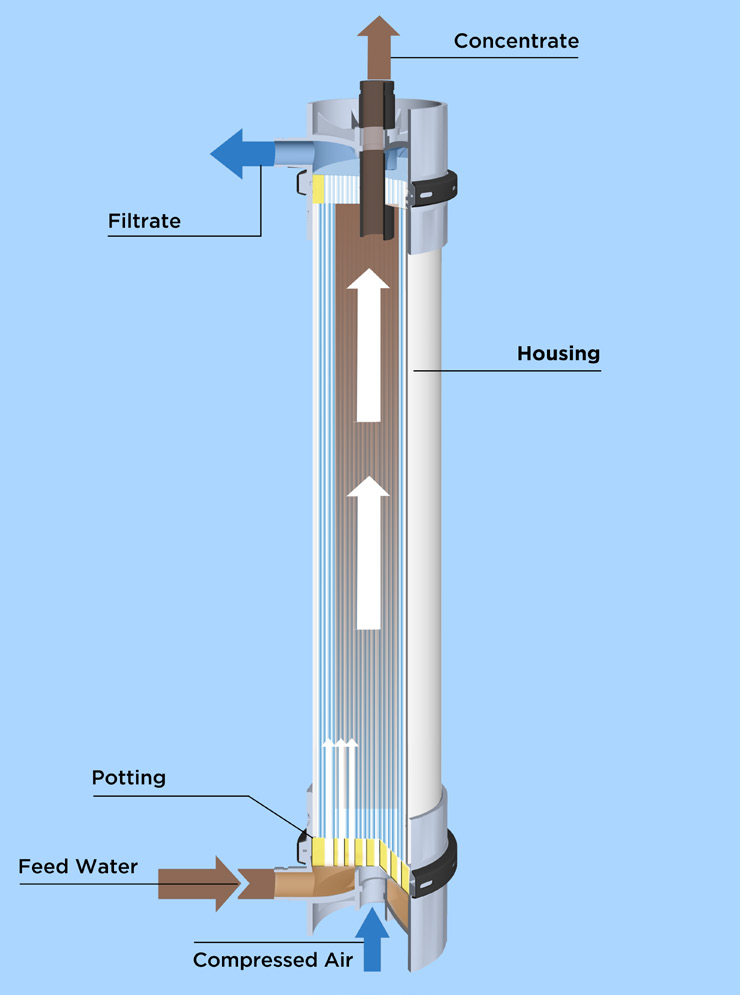

Ultrafiltration (UF) is a pressure-driven purification process that separates particulate matter from soluble compounds using an ultrafine membrane media. Ultrafiltration is an excellent separation technology for desalination pretreatment, reverse osmosis pretreatment, and wastewater reclamation, as well as for producing potable water.

Superior to sand filters and traditional media filtration

As with most conventional filtration methods, sand filters and media filtration require consistent raw water quality to deliver quality effluent, which is not always possible. They also don’t provide an absolute barrier. Traditional media filters typically remove particles to down to about 5 microns.

Ultrafiltration (UF), however, does not suffer from those limitations. This technology uses an ultrafiltration membrane barrier to exclude particles 0.02 to 0.05 microns, including bacteria, viruses, and colloids, meeting increasingly stringent water-quality standards around the world, and providing a stable, reliable, and consistent water quality.

UF offers:

- High and consistent product quality measured by turbidity (NTU) or silt density index (SDI).

- Tolerance to feedwater quality upsets.

- No use of pretreatment chemicals (polymer, coagulant, pH adjustment) and associated costs for sludge disposal.

- Small footprint and less weight than media filters.

When used as a pretreatment for reverse osmosis (RO), UF also helps reduce fouling of the RO membranes, which can lead to:

- Reduced chemical cleaning frequency and consequently, lower operating costs and downtime.

- The potential to operate RO at higher flux, with fewer membranes and vessels — leading to lower capital cost for the RO system.

SCINOR

SCINOR

THE GLOBAL LEADER IN DIRECT MF/UF RETROFITS. UNMATCHED TIPS PVDF PERFORMANCE.

THE GLOBAL LEADER IN DIRECT MF/UF RETROFITS. UNMATCHED TIPS PVDF PERFORMANCE.

Description

Scinor is a leading manufacturer of low-pressure hollow fiber membranes used throughout the world for water treatment. Since 2009, we have been supplying water filtration membranes for the industrial, desalination, municipal, and wastewater treatment industries. Our membrane filtration technology is the gold standard for performance and value in the water treatment industry.

Our Thermally Induced Phase Separation (TIPS) technology is used in all of our UF membrane products. Scinor’s patented, state-of-the-art materials and technology create membranes that are constructed to give customers the best performance, best service life and most cost-effective solution.

We can direct retrofit to other UF brands such as Dow, Toray, Hydranautics, Koch, GE/Suaz, Evoque Memcor, Polimem, Zee Weed, Motimo, Norit, Others. Please contact our marketing support to find your Scinor direct retrofit replacement.

Scinor is a leading manufacturer of low-pressure hollow fiber membranes used throughout the world for water treatment. Since 2009, we have been supplying water filtration membranes for the industrial, desalination, municipal, and wastewater treatment industries. Our membrane filtration technology is the gold standard for performance and value in the water treatment industry.

Our Thermally Induced Phase Separation (TIPS) technology is used in all of our UF membrane products. Scinor’s patented, state-of-the-art materials and technology create membranes that are constructed to give customers the best performance, best service life and most cost-effective solution.

We can direct retrofit to other UF brands such as Dow, Toray, Hydranautics, Koch, GE/Suaz, Evoque Memcor, Polimem, Zee Weed, Motimo, Norit, Others. Please contact our marketing support to find your Scinor direct retrofit replacement.

The Scinor Advantages

The Scinor Advantages

A Refreshing Customer-Focused Approach to Support and Continued Optimization

Scinor isn’t your typical ultrafiltration company—we work directly with customers, providing personalized service and a long-term commitment to help them optimize their plant’s operations. Our cost effective, state-of-the-art TIPS membranes are at the heart of our offerings.

Industry Leader in Direct Retrofit Solutions

We make it easy—our TIPS ultrafiltration membranes are constructed for direct replacement of all major hollow fiber filter modules.

Direct Retrofit Solutions mean: No additional hardware required, No programming adjustments, No process changes.

This versatility, coupled with superior TIPS (Thermally Induced Phase Separation) technology, gives our customers a higher performing, better value replacement product. Customers also benefit from lower capital and operating expenses.

Retrofit UF Filter Replacement

- Ultrafiltration Membrane Replacement | UF Filter Replacements

- Scinor Retrofit Modules | Direct Retrofit Replacement

- Ultrafiltration Membrane Replacement Has Never Been Easier

A Refreshing Customer-Focused Approach to Support and Continued Optimization

Scinor isn’t your typical ultrafiltration company—we work directly with customers, providing personalized service and a long-term commitment to help them optimize their plant’s operations. Our cost effective, state-of-the-art TIPS membranes are at the heart of our offerings.

Industry Leader in Direct Retrofit Solutions

We make it easy—our TIPS ultrafiltration membranes are constructed for direct replacement of all major hollow fiber filter modules.

Direct Retrofit Solutions mean: No additional hardware required, No programming adjustments, No process changes.

This versatility, coupled with superior TIPS (Thermally Induced Phase Separation) technology, gives our customers a higher performing, better value replacement product. Customers also benefit from lower capital and operating expenses.

Retrofit UF Filter Replacement

- Ultrafiltration Membrane Replacement | UF Filter Replacements

- Scinor Retrofit Modules | Direct Retrofit Replacement

- Ultrafiltration Membrane Replacement Has Never Been Easier

Thermally Induced Phase Separation (TIPS)

PVDF Membranes

In recent years, the large majority of ultrafiltration membrane manufacturers have adopted polyvinylidene fluoride (PVDF) as the polymer of choice for creating hollow fiber membranes for demanding water applications. The requirements for high flux rates, appropriate pore size, reliable membrane integrity, mechanical strength and durability, cleaning chemical compatibility, and relatively low cost, have made PVDF the choice over other polymers such as PAN, PES, and PE, and alternative materials such as ceramic membranes.

While not commonly known in the industry, there are two basic methods for creating PVDF membranes that result in significantly different end-products: Thermally Induced Phase Separation (TIPS) methods and Non-solvent Induced Phase Separation (NIPS).

The technology that Scinor uses to build membranes gives as a distinct advantage from our competition. With state-of-the-art materials and technology our UF membranes are constructed to give our customers the best service life and cost effective solution.

We use state-of-the-art materials and manufacturing techniques to provide affordable and versatile water filtration solutions. Scinor water ultrafiltration membranes can filter high volumes of water with superior efficiency, service life and operational cost. Our proprietary Thermally Induced Phase Separation (TIPS) manufacturing process.

For further information, please contact our marketing support.

Thermally Induced Phase Separation (TIPS)

PVDF Membranes

In recent years, the large majority of ultrafiltration membrane manufacturers have adopted polyvinylidene fluoride (PVDF) as the polymer of choice for creating hollow fiber membranes for demanding water applications.

Retrofit UF Filter Replacement

You now have a choice. This versatility, coupled with superior TIPS (Thermally Induced Phase Separation) technology, gives our customers a higher performing, better value replacement product. Customers also benefit from lower capital and operating expenses.

Ultrafiltration Membrane Replacement | UF Filter Replacements

You have a choice when it comes to costly UF filter replacements. Scinor’s UF membrane replacements use our state-of-the-art TIPS membranes, offering the most versatile, reliable and economical replacement filters on the market.

Scinor Retrofit Modules | Direct Retrofit Replacement

Direct retrofit UF filter replacements are the answer for hollow fiber membranes that have lost integrity, permeability, or reached the end of their service life – and even if they haven’t lived up to expectations. You now have a choice.

Ultrafiltration Membrane Replacement Has Never Been Easier

- No special hardware

- No programming adjustments

- No process changes

- No cleaning protocol changes

For further explanation, please contact our marketing support.

Retrofit UF Filter Replacement

Ultrafiltration Membrane Replacement | UF Filter Replacements

You have a choice when it comes to costly UF filter replacements. Scinor’s UF membrane replacements use our state-of-the-art TIPS membranes, offering the most versatile, reliable and economical replacement filters on the market.

Scinor Retrofit Modules | Direct Retrofit Replacement

Direct retrofit UF filter replacements are the answer for hollow fiber membranes that have lost integrity, permeability, or reached the end of their service life – and even if they haven’t lived up to expectations. You now have a choice.

Ultrafiltration Membrane Replacement Has Never Been Easier

- No special hardware

- No programming adjustments

- No process changes

- No cleaning protocol changes

For further explanation, please contact our marketing support.

You now have a choice. This versatility, coupled with superior TIPS (Thermally Induced Phase Separation) technology, gives our customers a higher performing, better value replacement product. Customers also benefit from lower capital and operating expenses.

| Characteristic | Scinor vs Asahi | Scinor vs NIPS | Benefit |

| Flux | Equal | 2.5x | Higher efficiency –> Fewer modules required per plant |

| Strength | Equal | 2.3x | Reduced breakage –> Reduced operational cost, extended life, highest WQ |

| Chemical resistance | Equal | 5x | Longer life –> Lower cost of ownership |

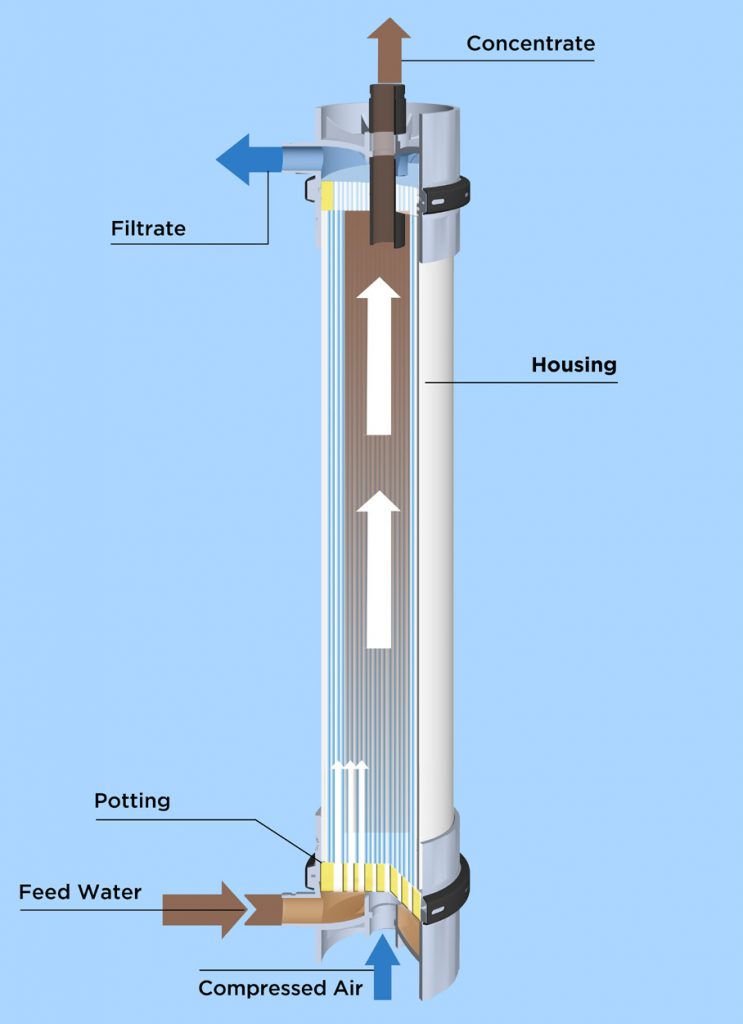

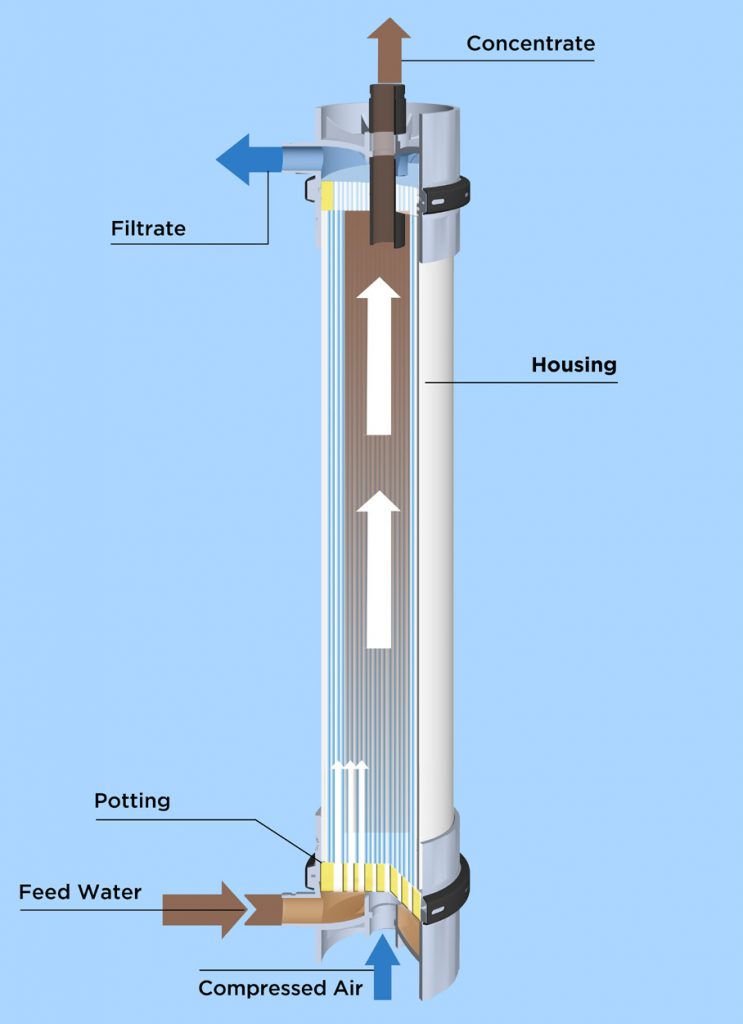

Scinor® SMT600–P51

Direct Retrofit to DOW SFP2860

Scinor SMT600 series ultrafiltration modules utilizing our state of-the-art Thermally Induced Phase Separation (TIPS) PVDF membranes provide the highest permeability, mechanical strength, and chemical tolerance in the industry. These modules are ideal for use in potable water, wastewater, desalination, and industrial applications. The SMT600-P51 retrofits major membrane vendor installations giving end-users a choice when replacing membranes.

The SMT600-P51 is an outside-in configuration module that operates in dead-end or cross-flow mode depending on specifics of the application. Cleaning processes used are simple backwash, maintenance clean, and Clean-in-Place.

| Part Number | SMT600-P51 |

| Fiber Material | Polyvinylidene Fluoride (PVDF) |

| Effective Area | 548 ft² (51 m²) |

| Nominal Pore Size | 0.1 μm |

| Fiber ID/OD | 0.7 mm/1.3 mm |

| Geometry | Ф225 mm×1860 mm |

| Port Size | DN50 |

| Housing/Head Material | U-PVC/ABS |

| Potting Material | Epoxy Resin |

| Temperature | 33-104° F (1-40 C) |

| pH Range | 1-11 Continuous |

| Max. NaClO | 5000 mg/L |

| Backwash Flux | 30-70 gfd (50-120 lmh) |

| Air Scour Flow | 3.1-7.5 scfm/module (5-12 Nm³/hr/module) |

| CIP pH Range | 1-13 |

| Max. Feed Pressure | 60 psi (0.4 MPa) |

| Max. TMP | 45 psi (0.3 MPa) |

| Operating TMP | 3-22 psi (0.02-0.15 MPa) |

| Max. Air Scour Pressure | 36 psi (0.25 MPa) |

| Max. Backwash Pressure | 36 psi (0.25 MPa) |

| Turbidity | ≤0.1 ntu |

| Silt Density Index | ≤3 |

| E.Coli Removal | non-detect |

Industrial

Wastewater

Drinking Water

Desalination

Download brochure here

Product Advantages

Product Advantages

Excellent Filtered Water Quality

- Tight 0.1 μm pore size distribution

- Low fiber breakage rate

Long Operational Life

- High mechanical strength and durability

- >5000 mg/L Sodium Hypochlorite tolerance

Low Capital Cost

- High flux rates on all water sources

Low Requirements for Pretreatment

- Outside-in configuration

- Optimal flow channel

Low Operating and Maintenance Requirements

- Low energy and chemical consumption due to higher permeability

- Automatic operation

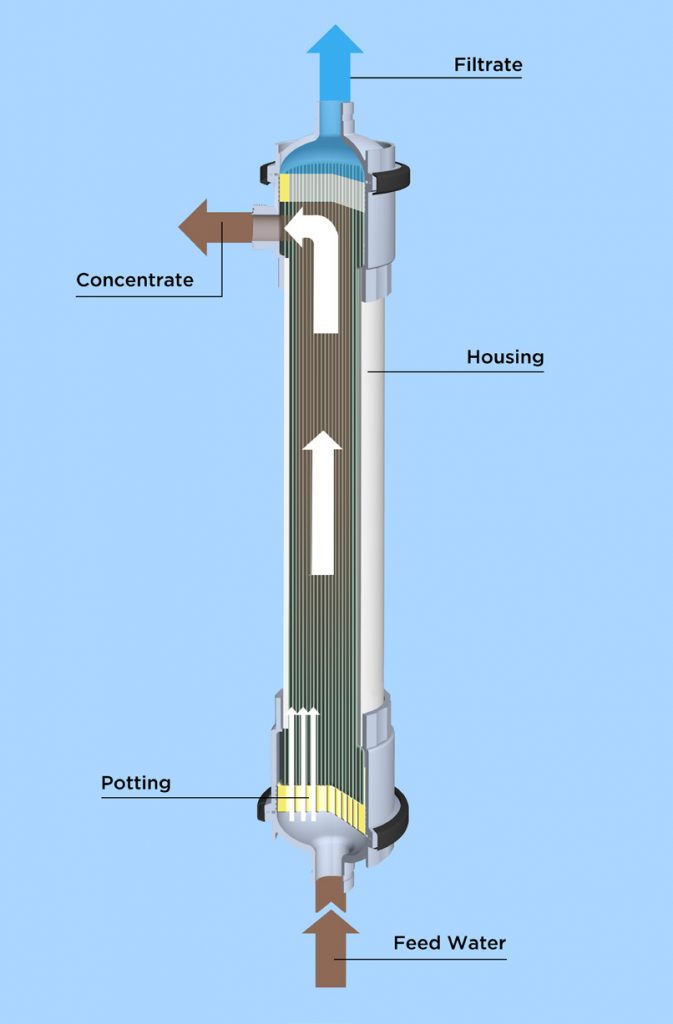

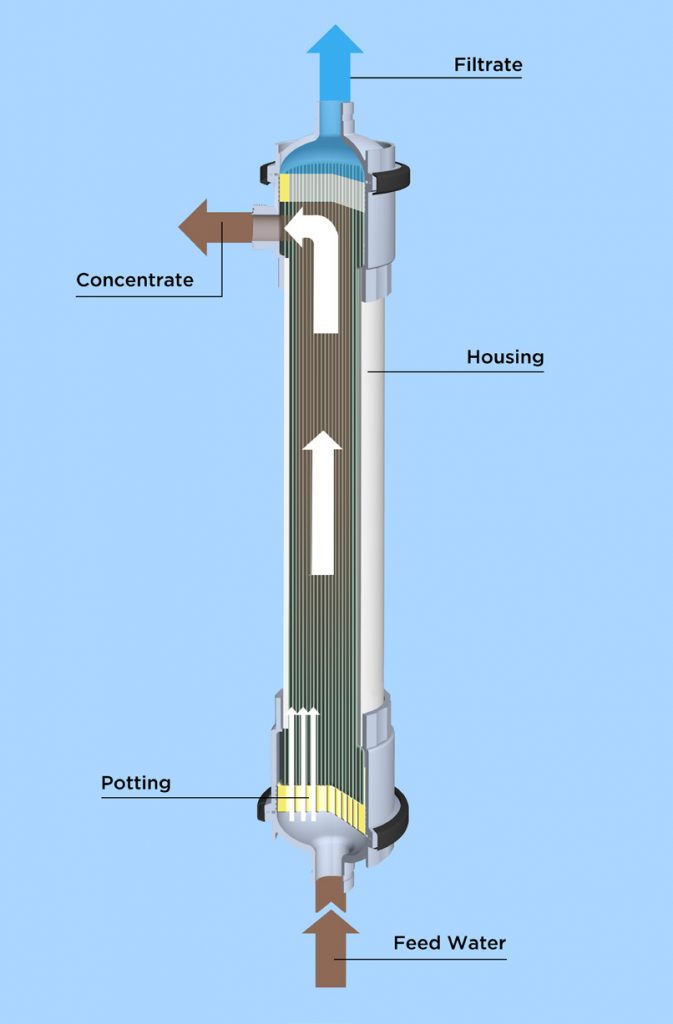

Scinor® SMT600–P72

Direct Retrofit to TORAY HSF2020 & Hydranautics Caps60

Scinor SMT600 series ultrafiltration modules utilizing our state of-the-art Thermally Induced Phase Separation (TIPS) PVDF membranes provide the highest permeability, mechanical strength, and chemical tolerance in the industry. These modules are ideal for use in portable water, wastewater, desalination, and industrial applications. The SMT600-P72 retrofits major membrane vendor installations giving end-users a choice when replacing membranes.

The SMT600-P72 is an outside-in configuration module that operates in dead-end or cross-flow mode depending on specifics of the application. Cleaning processes used are simple backwash, maintenance clean, and Clean-in-Place.

| Part Number | SMT600-P72 |

| Fiber Material | Polyvinylidene Fluoride (PVDF) |

| Effective Area | 775 ft² (72 m²) |

| Nominal Pore Size | 0.1 μm |

| Fiber ID/OD | 0.7 mm/1.3 mm |

| Geometry | Ф200 mm×2160 mm |

| Port Size | JIS 80A, Side JIS 65A |

| Housing/Head Material | U-PVC/ABS |

| Potting Material | Epoxy Resin |

| Temperature | 33-104° F (1-40 C) |

| pH Range | 1-13 Continuous |

| Max. NaClO | 5000 mg/L |

| Backwash Flux | 30-70 gfd (50-120 lmh) |

| Air Scour Flow | 3.1-7.5 scfm/module (5-12 Nm³/hr/module) |

| CIP pH Range | 1-13 |

| Max. Feed Pressure | 60 psi (0.4 MPa) |

| Max. TMP | 45 psi (0.3 MPa) |

| Operating TMP | 3-22 psi (0.02-0.15 MPa) |

| Max. Air Scour Pressure | 36 psi (0.25 MPa) |

| Max. Backwash Pressure | 36 psi (0.25 MPa) |

| Turbidity | ≤0.1 ntu |

| Silt Density Index | ≤3 |

| E.Coli Removal | non-detect |

| LRV, Virus | 3.98 |

| LRV, Cryptosporidium | >6.0 |

Industrial

Wastewater

Drinking Water

Desalination

Download brochure here

Product Advantages

Product Advantages

Excellent Filtered Water Quality

- >3.5 log virus removal and >6 log crypto removal

- Low ber breakage rate

Long Operational Life

- High mechanical strength and durability

- >5000 mg/L Sodium Hypochlorite tolerance

Low Capital Cost

- High flux rates on all water sources

Low Requirements for Pretreatment

- Outside-in configuration

- Optimal flow channel

Low Operating and Maintenance Requirements

- Low energy and chemical consumption due to higher permeability

- Automatic operation

Scinor® SMT600–P80

Direct Retrofit to DOW SFP2880

Scinor SMT600 series ultra ltration modules utilizing our state-of-the-art Thermally Induced Phase Separation (TIPS) PVDF membranes provide the highest permeability, mechanical strength, and chemical tolerance in the industry. These modules are ideal for use in potable water, wastewater, desalination, and industrial applications. The SMT600-P80 retrofits major membrane vendor installations giving end-users a choice when replacing membranes.

The large and reliable SMT600-P80 pressurized ultrafiltration module is suitable for large-scale water treatment plants due to high permeability and high fiber packing density which reduces overall system footprint and lowers system capital cost.

The SMT600-P80 is an outside-in configuration module that operates in dead-end or cross-flow mode depending on specifics of the application. Cleaning processes used are simple backwash, maintenance clean, and Clean-in-Place.

| Part Number | SMT600-P80 |

| Fiber Material | Polyvinylidene Fluoride (PVDF) |

| Effective Area | 861 ft² (80 m²) |

| Nominal Pore Size | 0.1 μm |

| Fiber ID/OD | 0.7 mm/1.3 mm |

| Geometry | Ф225 mm×2360 mm |

| Port Size | DN50 |

| Housing/Head Material | U-PVC/ABS |

| Potting Material | Epoxy Resin |

| Temperature | 33-104° F (1-40 C) |

| pH Range | 1-11 Continuous |

| Max. NaClO | 5000 mg/L |

| Backwash Flux | 30-70 gfd (50-120 lmh) |

| Air Scour Flow | 3.1-7.5 scfm/module (5-12 Nm³/hr/module) |

| CIP pH Range | 1-13 |

| Max. Feed Pressure | 60 psi (0.4 MPa) |

| Max. TMP | 45 psi (0.3 MPa) |

| Operating TMP | 3-22 psi (0.02-0.15 MPa) |

| Max. Air Scour Pressure | 36 psi (0.25 MPa) |

| Max. Backwash Pressure | 36 psi (0.25 MPa) |

| Turbidity | ≤0.1 ntu |

| Silt Density Index | ≤3 |

| E.Coli Removal | non-detect |

Industrial

Wastewater

Drinking Water

Desalination

Scinor® RT-P600H

Direct Retrofit to Hyflux K600ER/B

Scinor RT-P600H ultrafiltration modules utilizing our state of-the-art Thermally Induced Phase Separation (TIPS) PVDF membranes provide the highest permeability, mechanical strength, and chemical tolerance in the industry. These modules are ideal for use in portable water, wastewater, desalination, and industrial applications. Cleaning processes used are simple backwash, maintenance clean, and Clean-in-Place.

| Part Number | RT-P600H |

| Fiber Material | Polyvinylidene Fluoride (PVDF) |

| Effective Area | 60 m² |

| Nominal Pore Size | 0.1 μm |

| Fiber ID/OD | 0.7 mm/1.3 mm |

| Geometry | Ф225 mm×2360 mm |

| Housing/Head Material | U-PVC/ABS |

| Potting Material | Epoxy Resin |

| Temperature | 33-104° F (1-40 C) |

| pH Range | 1-11 Continuous |

| Max. NaClO | 5000 mg/L |

| Backwash Flux | 30-70 gfd (50-120 lmh) |

| Air Scour Flow | 3.1-7.5 scfm/module (5-12 Nm³/hr/module) |

| CIP pH Range | 1-13 |

| Max. Feed Pressure | 60 psi (0.4 MPa) |

| Max. TMP | 45 psi (0.3 MPa) |

| Operating TMP | 3-22 psi (0.02-0.15 MPa) |

| Max. Air Scour Pressure | 36 psi (0.25 MPa) |

| Max. Backwash Pressure | 36 psi (0.25 MPa) |

| Turbidity | ≤0.1 ntu |

| Silt Density Index | ≤3 |

| E.Coli Removal | non-detect |

| LRV, Virus | 3.98 |

| LRV, Cryptosporidium | >6.0 |

Industrial

Wastewater

Drinking Water

Desalination

| Part Number | RT-P600H |

| Fiber Material | Polyvinylidene Fluoride (PVDF) |

| Effective Area | 60 m² |

| Nominal Pore Size | 0.1 μm |

| Fiber ID/OD | 0.7 mm/1.3 mm |

| Geometry | Ф225 mm×2360 mm |

| Housing/Head Material | U-PVC/ABS |

| Potting Material | Epoxy Resin |

| Temperature | 33-104° F (1-40 C) |

| pH Range | 1-11 Continuous |

| Max. NaClO | 5000 mg/L |

| Backwash Flux | 30-70 gfd (50-120 lmh) |

| Air Scour Flow | 3.1-7.5 scfm/module (5-12 Nm³/hr/module) |

| CIP pH Range | 1-13 |

| Max. Feed Pressure | 60 psi (0.4 MPa) |

| Max. TMP | 45 psi (0.3 MPa) |

| Operating TMP | 3-22 psi (0.02-0.15 MPa) |

| Max. Air Scour Pressure | 36 psi (0.25 MPa) |

| Max. Backwash Pressure | 36 psi (0.25 MPa) |

| Turbidity | ≤0.1 ntu |

| Silt Density Index | ≤3 |

| E.Coli Removal | non-detect |

| LRV, Virus | 3.98 |

| LRV, Cryptosporidium | >6.0 |

Industrial

Wastewater

Drinking Water

Desalination

Let’s work together with

Hidro Dinamika Kencana

water treatment specialist in Indonesia

Engineering | Procurement | Construction

Let’s work together with

Hidro Dinamika Kencana

water treatment specialist in Indonesia

Engineering | Procurement | Construction