Reverse Osmosis System

Overcoming Osmotic Pressure

In ordinary osmosis, when a semipermeable membrane separates solutions of differing solute concentrations, the lower-concentration solution flows into the higher-concentration solution in attempt to reach equilibrium: an equal degree of solute concentration on both sides of the membrane. As the amount of solution on the higher-concentration side increases, pressure on that water column rises until it is high enough to hinder the flow of the lower-concentration solution across the membrane. This is the action of osmotic pressure.

In reverse osmosis (RO), pressure that exceeds a system’s osmotic pressure is applied to that system. The pressure forces the higher-concentration solution back across the semipermeable membrane, leaving solutes that are blocked by the semipermeable membrane behind.

Typically, reverse osmosis water treatment results in a rejection of dissolved salts that is 95 – 99 percent or greater, depending on membrane type, feed composition, temperature, and system design.

Reverse osmosis water treatment can provide finer filtration than either nanofiltration or ultrafiltration. Using RO as a pretreatment process for ion exchange (IX) can substantially reduce the operating costs and regeneration frequency of the IX system.

Typical applications include:

- Purification of home drinking water.

- Desalination of seawater or brackish water to produce drinking water.

- Wastewater recovery.

- Food and beverage processing.

- Biomedical separation.

- Industrial process water treatment.

Reverse osmosis water treatment is also often used to produce ultrapure water for the semiconductor industry , in boiler water treatment for the power industry, and for applications in the health care and bioprocessing industry.

Reverse Osmosis System

Overcoming Osmotic Pressure

In ordinary osmosis, when a semipermeable membrane separates solutions of differing solute concentrations, the lower-concentration solution flows into the higher-concentration solution in attempt to reach equilibrium: an equal degree of solute concentration on both sides of the membrane. As the amount of solution on the higher-concentration side increases, pressure on that water column rises until it is high enough to hinder the flow of the lower-concentration solution across the membrane. This is the action of osmotic pressure.

In reverse osmosis (RO), pressure that exceeds a system’s osmotic pressure is applied to that system. The pressure forces the higher-concentration solution back across the semipermeable membrane, leaving solutes that are blocked by the semipermeable membrane behind.

Typically, reverse osmosis water treatment results in a rejection of dissolved salts that is 95 – 99 percent or greater, depending on membrane type, feed composition, temperature, and system design.

Reverse osmosis water treatment can provide finer filtration than either nanofiltration or ultrafiltration. Using RO as a pretreatment process for ion exchange (IX) can substantially reduce the operating costs and regeneration frequency of the IX system.

Typical applications include:

- Purification of home drinking water.

- Desalination of seawater or brackish water to produce drinking water.

- Wastewater recovery.

- Food and beverage processing.

- Biomedical separation.

- Industrial process water treatment.

Reverse osmosis water treatment is also often used to produce ultrapure water for the semiconductor industry , in boiler water treatment for the power industry, and for applications in the health care and bioprocessing industry.

HYDRANAUTICS

THE GLOBAL LEADER IN MEMBRANE TECHNOLOGY

Hydranautics is one of the global leaders in membrane technology. Hydranautics’ products are currently in use on all seven continents. Product applications include potable water, boiler feedwater, industrial process water, wastewater treatment, surface water treatment, seawater desalination, residential water, electronic rinse water, agricultural irrigation and pharmaceuticals.

A network of worldwide sales offices throughout the USA, South America, Europe and Asia support Hydranautics’ global business base. Hydranautics is the first membrane manufacturer to meet the highest quality standards with ISO 9001 Quality System Certification.

HYDRANAUTICS

THE GLOBAL LEADER IN MEMBRANE TECHNOLOGY

Hydranautics is one of the global leaders in membrane technology. Hydranautics’ products are currently in use on all seven continents. Product applications include potable water, boiler feedwater, industrial process water, wastewater treatment, surface water treatment, seawater desalination, residential water, electronic rinse water, agricultural irrigation and pharmaceuticals.

A network of worldwide sales offices throughout the USA, South America, Europe and Asia support Hydranautics’ global business base. Hydranautics is the first membrane manufacturer to meet the highest quality standards with ISO 9001 Quality System Certification.

We offer results :

Integrated Membrane Solution (IMS)

Our Integrated Membrane Solution (IMS) are customized membrane solutions to meet specific business objectives and offer comprehensive technical support in the development of new technology.

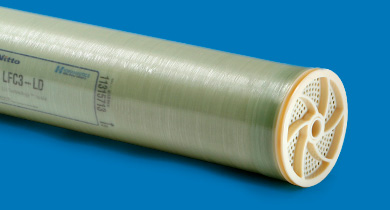

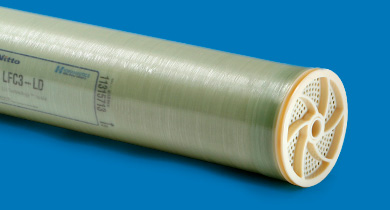

LD technology™

LD technology™ products are globally used for various applications for Brackish water, sea water desalination, waste water treatment etc. This new generation LD RO elements have been effectively used on difficult feedwater plants, including those treating reclaimed wastewater, surface water and difficult well waters.

We offer results :

Integrated Membrane Solution (IMS)

Our Integrated Membrane Solution (IMS) are customized membrane solutions to meet specific business objectives and offer comprehensive technical support in the development of new technology.

LD technology™

LD technology™ products are globally used for various applications for Brackish water, sea water desalination, waste water treatment etc. This new generation LD RO elements have been effectively used on difficult feedwater plants, including those treating reclaimed wastewater, surface water and difficult well waters.

Hydranautics – LD Technology™

Introduction

When high performance is required under demanding conditions, the LD (Low Differential) reverse osmosis / nanofiltration membrane elements from Hydranautics -A Nitto Group Company set a new standard for high performance with lower colloidal fouling.

Enhanced Membrane Chemistry

- To increase chemical resistance and high pH tolerance

- Increase element life

Innovative Spacer Design

- To minimize trapping of small colloidal particles

- Reduce pressure losses

- Increase system efficiency

Patented Vented Seal Carrier

- Eliminates pressure shock damage during system startup

Lower Colloidal Fouling

- Innovative feed spacer design prevents trapping of small colloidal particles and reduces the colloidal fouling of RO/NF membranes.

Increased Membrane Durability

- Enhanced membrane chemistry provides increased chemical resistance to high pH operation.

- Patented seal carrier has air vents to allow quick passage of residual air between the membrane elements during the system start-up to prevent element damage due to pressure shock.

Enhanced Cleaning Performance

- The LD Technology offers a wide pH cleaning range so that effective cleaning can be performed without degrading performance.

Lower dP (Differential Pressure)

- Lower differential pressure reduces power consumption, saving energy costs and decreasing the carbon footprint of the system.

Improved Flux Distribution

- Lower differential pressure also improves flux distribution between lead and tail element further reducing membrane fouling.

Key Benefits

- Longer membrane life

- Reduced cleaning costs

- Increased productivity

- Improved permeate quality

Applications

- Surface water and waste water sources with high fouling potential

- Ultrapure water production for semiconductor and pharmaceuticals industries

- Boiler feed water for power generation and manufacturing industries

- Waste water reuse

- Brackish water RO for drinking water

- Seawater RO for drinking water

For further explanation, please contact our marketing support.

Hydranautics – LD Technology™

Introduction

When high performance is required under demanding conditions, the LD (Low Differential) reverse osmosis / nanofiltration membrane elements from Hydranautics -A Nitto Group Company set a new standard for high performance with lower colloidal fouling.

For further explanation, please contact our marketing support.

Key Features

Enhanced Membrane Chemistry

- To increase chemical resistance and high pH tolerance

- Increase element life

Innovative Spacer Design

- To minimize trapping of small colloidal particles

- Reduce pressure losses

- Increase system efficiency

Patented Vented Seal Carrier

- Eliminates pressure shock damage during system startup

The LD Advantages

Lower Colloidal Fouling

-

Innovative feed spacer design prevents trapping of small colloidal particles and reduces the colloidal fouling of RO/NF membranes.

Increased Membrane Durability

- Enhanced membrane chemistry provides increased chemical resistance to high pH operation.

- Patented seal carrier has air vents to allow quick passage of residual air between the membrane elements during the system start-up to prevent element damage due to pressure shock.

Enhanced Cleaning Performance

- The LD Technology offers a wide pH cleaning range so that effective cleaning can be performed without degrading performance.

Lower dP (Differential Pressure)

- Lower differential pressure reduces power consumption, saving energy costs and decreasing the carbon footprint of the system.

Improved Flux Distribution

- Lower differential pressure also improves flux distribution between lead and tail element further reducing membrane fouling.

Key Benefits

Key Benefits

-

Longer membrane life

-

Reduced cleaning costs

-

Increased productivity

-

Improved permeate quality

Applications

Applications

-

Surface water and waste water sources with high fouling potential

-

Ultrapure water production for semiconductor and pharmaceuticals industries

-

Boiler feed water for power generation and manufacturing industries

-

Waste water reuse

-

Brackish water RO for drinking water

-

Seawater RO for drinking water

SWRO – Sea Water Composite (SWC)

SWRO – Sea Water Composite (SWC)

As the world is facing freshwater scarcity, Hydranautics brings a range of SWC RO membranes to meet the demands of desalination industry. SWC membranes have improved the productivity and salt rejection for more than two decades while reducing their environmental impact. SWC membranes come in a range of innovative formulations depending on the level of seawater salinity required.ction rates.

BWRO – Composite Polyamide (CPA)

BWRO – Composite Polyamide (CPA)

Ultrapure water is essential in several industrial applications. CPA RO membranes are regarded as the industry standard for all critical high purity applications – from pharmaceutical to power industry. CPA lines of spiral-wound RO membranes are available in a variety of sizes and deliver unmatched performance with the highest salt rejection rates.

BWRO – Energy Saving Polyamide (ESPA)

BWRO – Energy Saving Polyamide (ESPA)

Energy required to pressurize RO feed water is the largest contributor to the total energy consumption of the RO plant. As a result, chlorine tolerant membranes have helped the membrane technology become affordable and cost effective by reducing energy consumption required to operate RO system. ESPA membranes are the choice for applications demanding high-energy efficiency, with uncompromised productivity and salt rejection.

BWRO – Low Fouling Composite (LFC)

BWRO – Low Fouling Composite (LFC)

LFC3-LD from the LD Technology™ innovative low fouling membranes combines the attributes of a neutrally charged surface with hydrophilicity to achieve the lowest organic and colloidal fouling in the most demanding feed water conditions. Combining the attributes of a neutral surface charge and hydrophilicity, LFC3-LD provides significant reduction in fouling rates increasing the membrane’s efficiency by restoring nominal performance after cleaning.

Let’s work together with

Hidro Dinamika Kencana

water treatment specialist in Indonesia

Engineering | Procurement | Construction

Let’s work together with

Hidro Dinamika Kencana

water treatment specialist in Indonesia

Engineering | Procurement | Construction